STEP 1

Requirement Analysis

Requirement Analysis

Fully understand and satisfy customer's requirements is our top priority. When received your initial CAD data and gathered your technical requirements package, the main focus of this phase is

Identification and definition of all technical, commerical and timely project requirements and conditions together with customer

Detail requirement analysis in regards of realization for an economical and efficient way of manufacturing with the BAOFA solution

Submission of our detailed price quotation for your approval

Throughout the design process, our skilled engineers work together with you and your team to recognize weak points at casting and machining steps and optimize them early in the development process. Engaging us as partners at the begining design process has proven to lead to optimal technical and commercial outcomes.

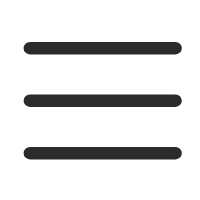

Modern engineering techniques:

Material simulation

FEM calculation

Mold filling and solidification simulation

Stress and deformation simulation

Tooling maker early involvement

Simulation | Jointly design

Technical Project Management

The project engineering process is an essential part of our organization. Your dedicated program manager leads and manages a cross-functional launch team during product development to achieve on time delivery of casting components and required quality standards.

Multi-project planning/Resource planning

Management of deadlines, costs and level of maturity

Gateway monitoring for design, release, procurement, production phases

Standardized scheduling, reporting and escalation systems

Working according to your requirements and specifications, we provide customized planning for the measuring and testing procedures for your precision castings early at the quotation stage. This allows achievement of a stable process for high volume series precision casting production.

Qualtiy Validation methods:

Mechnical properties testing

X-ray detection

Check fixture concept review

CMM dimensional mensurements

Digital scanning of the casting and tooling

Phased OTS and PPAP sampling process

ISIR Sampling

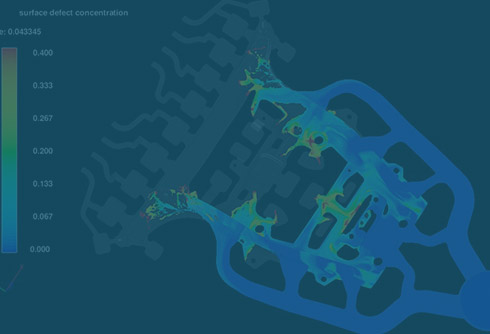

Series Prodution

BAOFA PRECISION is one of the few China casting foundry to offer highly integrates casting services that include high and low pressure die casting, gravity die casting and precison investment casting under one roof, along with heat treatment and CNC machining solutions, we are able to deliver effective solutions to any casting challenges.

Modern high pressure die casting machines from 320 to 2000 tons

Automated casting equipment with robotic work cells for process stability

Vacuum casting technology used when and where it is needed

Numbers of CNC machines are capable of medium to large volume machining

Custom assembly services while performing leak tests and functional testing

Surface finish capability such as painting, powder coating and anodizing with professional supply chain network

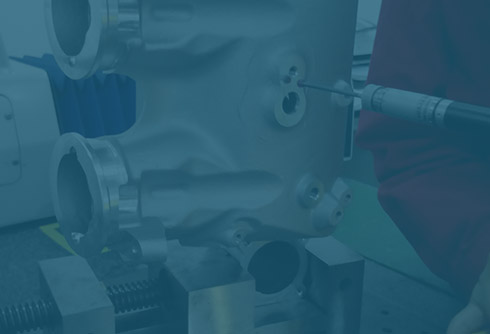

All the machined castings and casting assemblies are carefully packaged to prevent any possible damage and deterioriate during the delivery and shipping process.

Packaging concept based on your individual packaging specifications

Delivery terms as EXW, FCA and others available for the international shipping

Great relathionships with shippers and courier services

Casting Packaging|Delivery