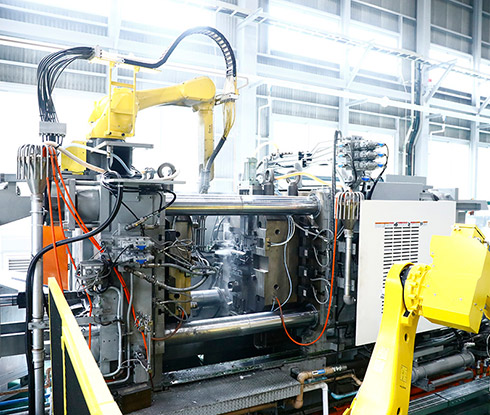

In the high-pressure die casting process, liquid alloy is injected at high speed and under high pressure into the moulds made of tool steel. High flow velocities occur in the casting mould throughout the casting process until the mould is filled. After the part is cast, it is trimmed and sent for a visual check. BAOFA PRECISION uses robotics as an integrated part of the manufacturing process.

BAOFA PRECISION produce high volume, complex geometry castings and assemblies for all areas of transmission, engine and driveline applications.