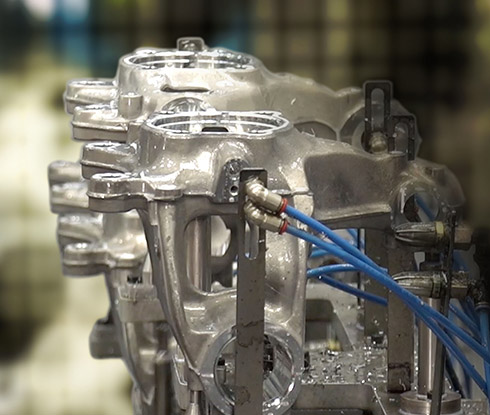

In the low pressure die casting process, the metal is transferred from an airtight furnace through a rising tube into a metallic tool. The molten metal is pushed upwards into the die with low pressure. The mould is filled up slowly, which ensures the solidity of the part with no wanted porosity or entrained gases. The pressure holds the metal in the die until it solidifies.

BAOFA PRECISION have extensive experience in low pressure die casting, we manufacture the safety-critical structural castings include knuckles, brackets and other more.