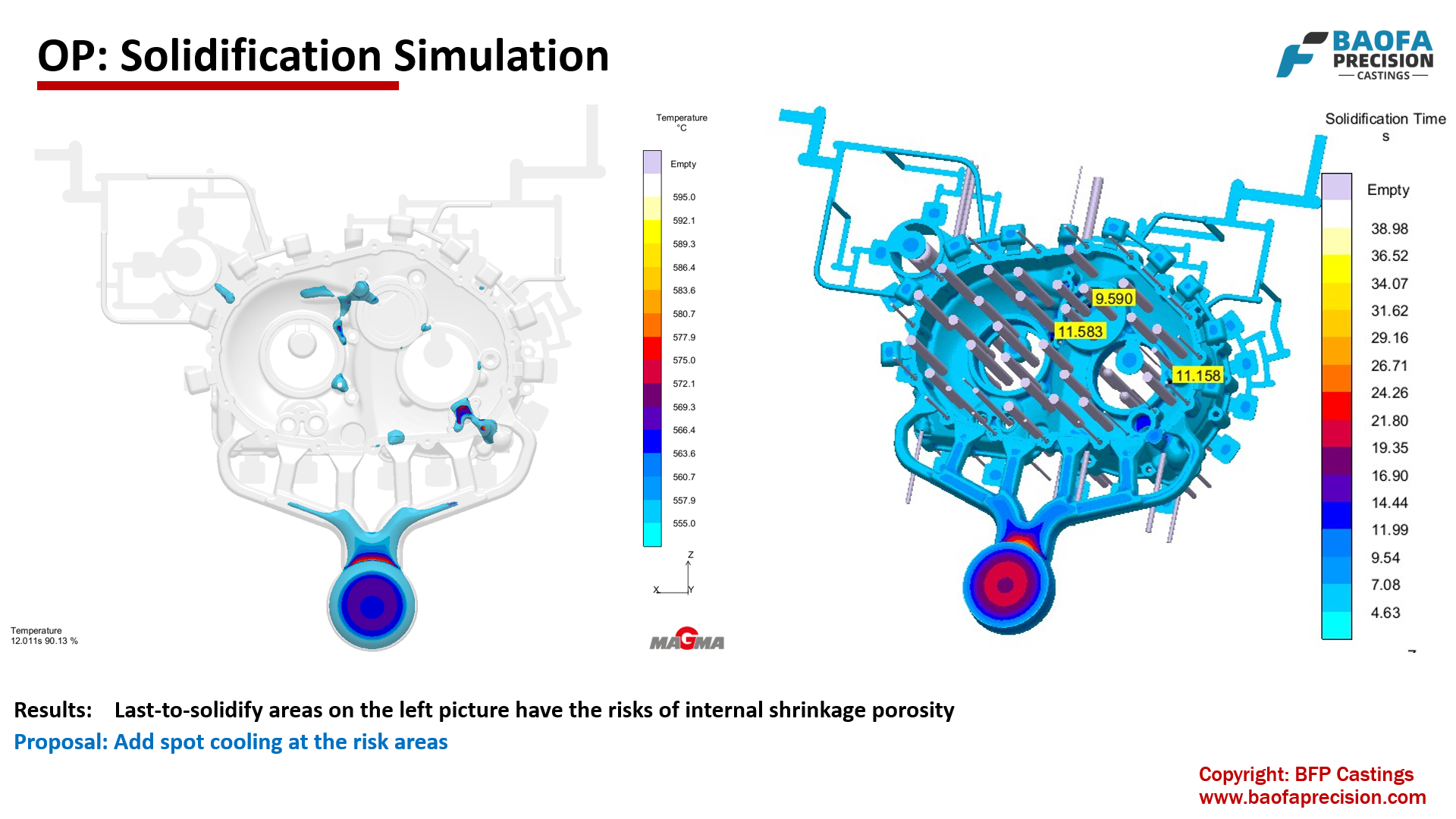

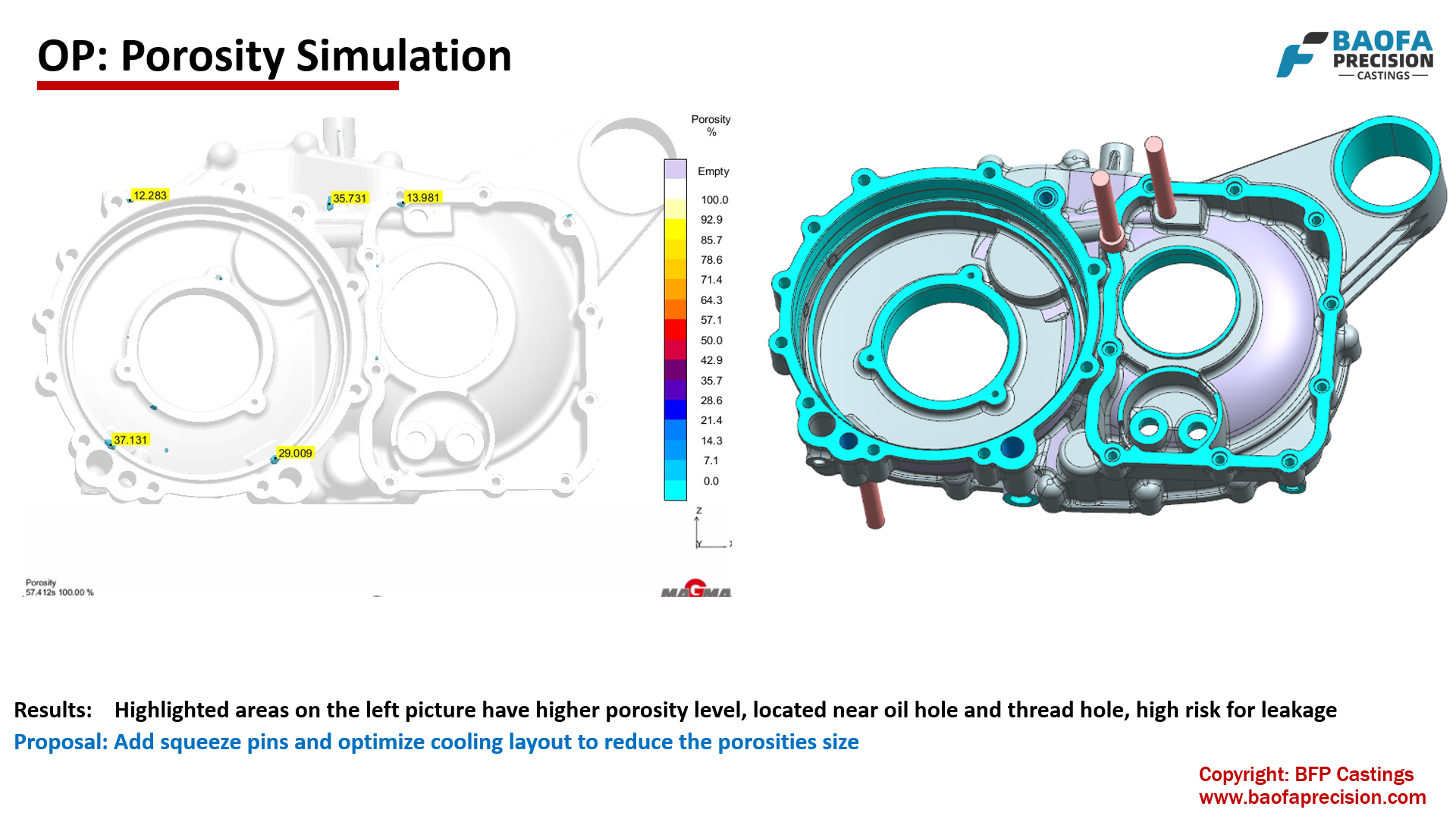

BFP engineering team use the advanced casting simulation software to predict and optimize potential aluminum casting defects such as porosity, air entrapment and solidification issues at an early stage of process development, to minimize the trail and error costs with maximized casting quality.

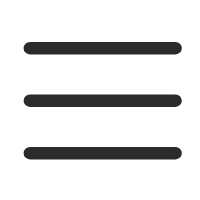

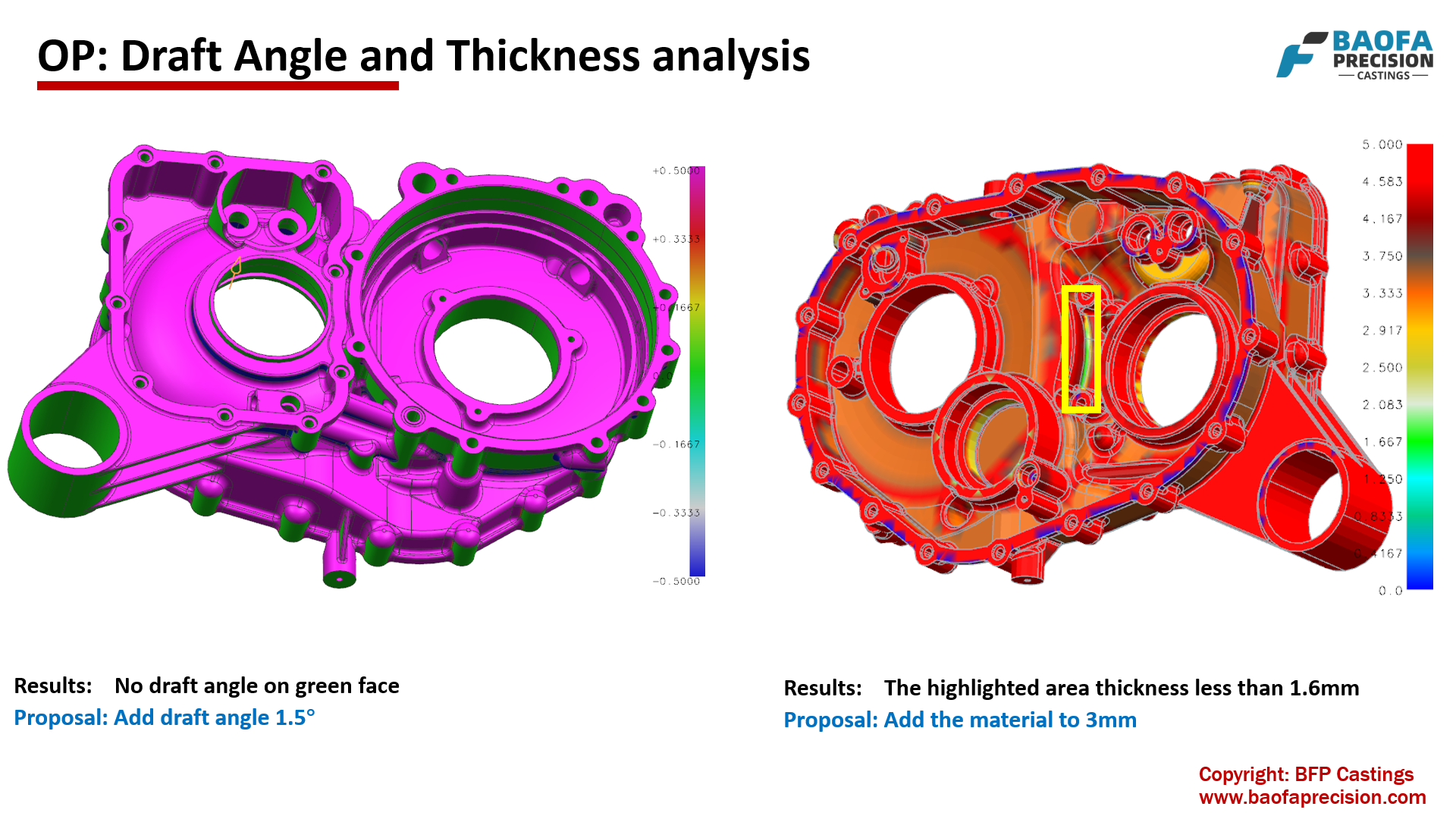

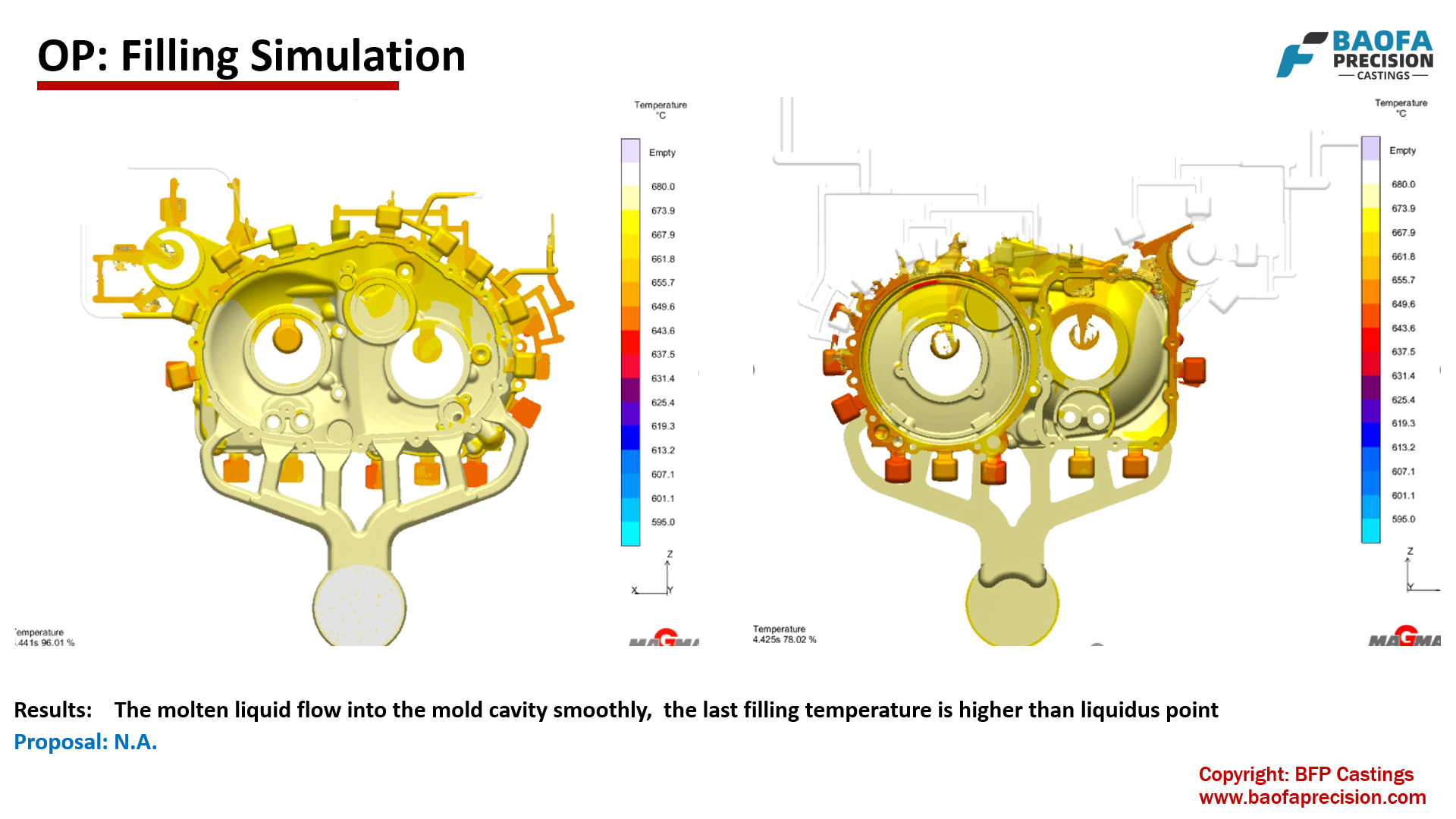

With deep knowledge of the simulation technologies, BFP engineering can predict and evaluation the entire casting processes, from the part draft angle analysis, tooling layout all the way to the mold filling, solidification and cooling. And the result is better gating, venting and cooling system design before making every mold.

Down below is an example of standardized casting simulation process performed at BFP Castings.

Using advanced cast simulation software combined with more than 20 years metal casting devleopment experience, BFP engineers have the capabilities to simulation the following processes for your next project:

High pressure die casting/High vacuum die casting

Low pressure die casting

Gravity/Permanent mold die casting

Investment casting

Contact us today and our engineers would love to assist both in your next demanding new projects as well as in the quality improvement of existing parts.

*All consultation services are completely free of charge.