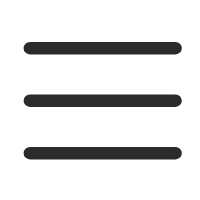

BFP Castings understands how important precision and accuracy is in the metal casting industry, that's why we use advanced 3D scanning technology to provide accurate measurements for our customers. With the help of high-accuracy scan arm, BFP quality engineers can quickly measure, inspect, analyze the casting dimensions before and after machining.

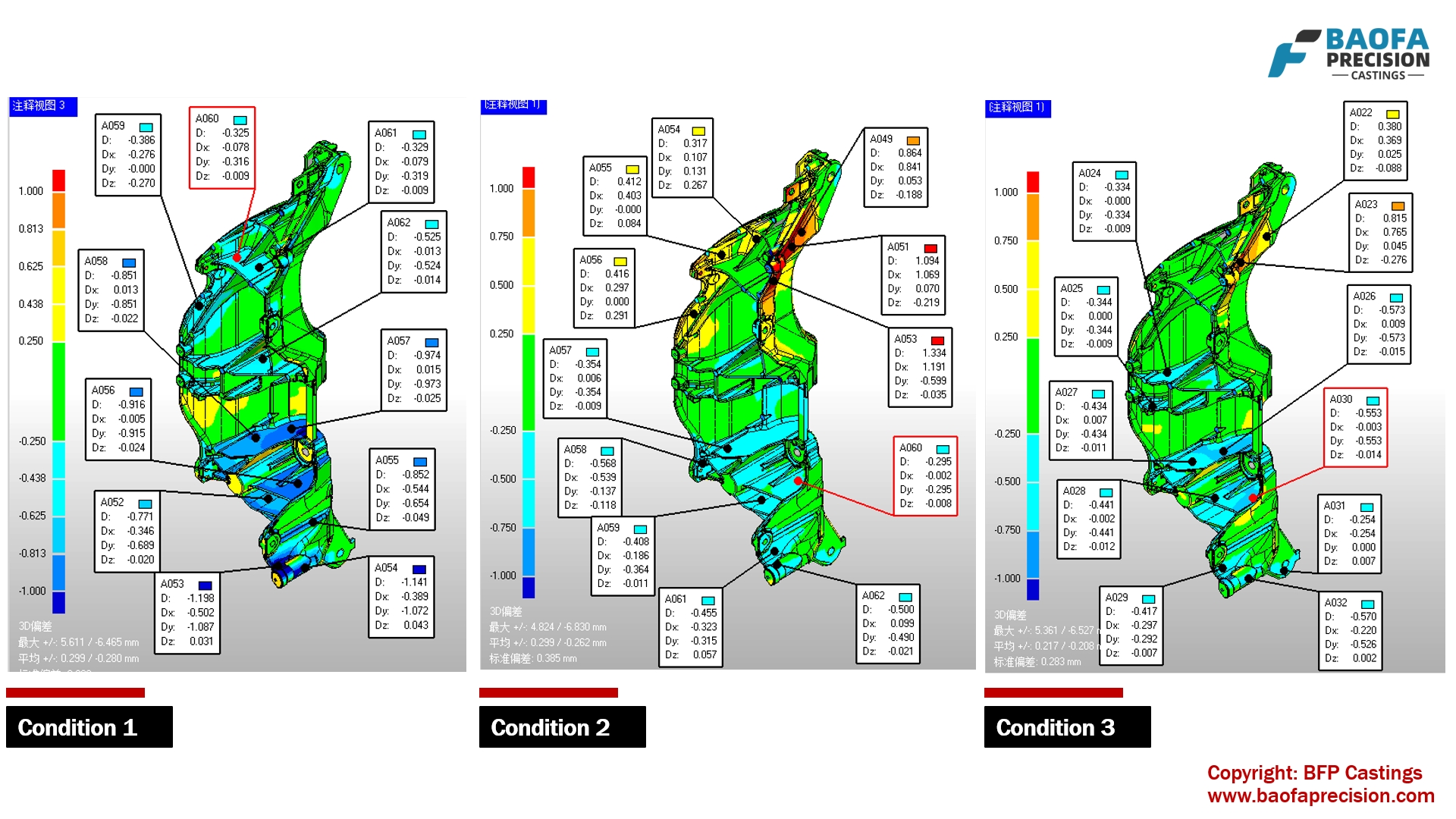

In analyzing the entire surface profiles, BFP engineering team can evaluate if the raw castings with acceptable deformation and enough material to proceed with machining.

Key benefits of metal casting 3D scanning:

Quickly identify the raw castings with potential issues such as shrinkage and deformation to reduce the scraps after machining

Much faster measurment time than traditional CMM and minimized the inspection time and cost

Easily visualize the part deviations at a glance through color map comparison

Quality Metal Castings by BAOFA Precision

BFP offers a wide variety of in-house casting quality control, verification and inspect services to provide our customers with the highest quality cast product.

Contact Us for more information on our metal casting inspection methods, we will gladly answer any questions that you may have for your application.