Metal casting industry is evolving fast with increased complex geometries, lighter-weight structures and zero-defect demand, but only if quality control can keep up. Traditional inspection methods struggle with internal shrinkage, voids, porosity issues in aluminium casting foundry. With advanced industrial CT scanning, we can reduce the risk of missed defects before they become production issues.

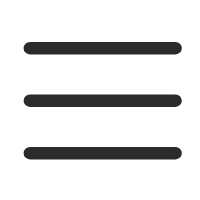

How does industrial CT scanning works

Industrial CT scanning operates on principles similar to medical CT scans but tailored for industrial applications. The process begins with the component being placed on a rotating platform within the CT scanner. Next, a poweful X-ray source emits radiation, which penetrates the object at many different angles as it rotates. The radiation that passes through the object is capatured by a detector on the other side. This interaction results in a series of 2D X-ray images, or "slices", which collectively generate detailed 3D model of the scanned casting's internal structure.

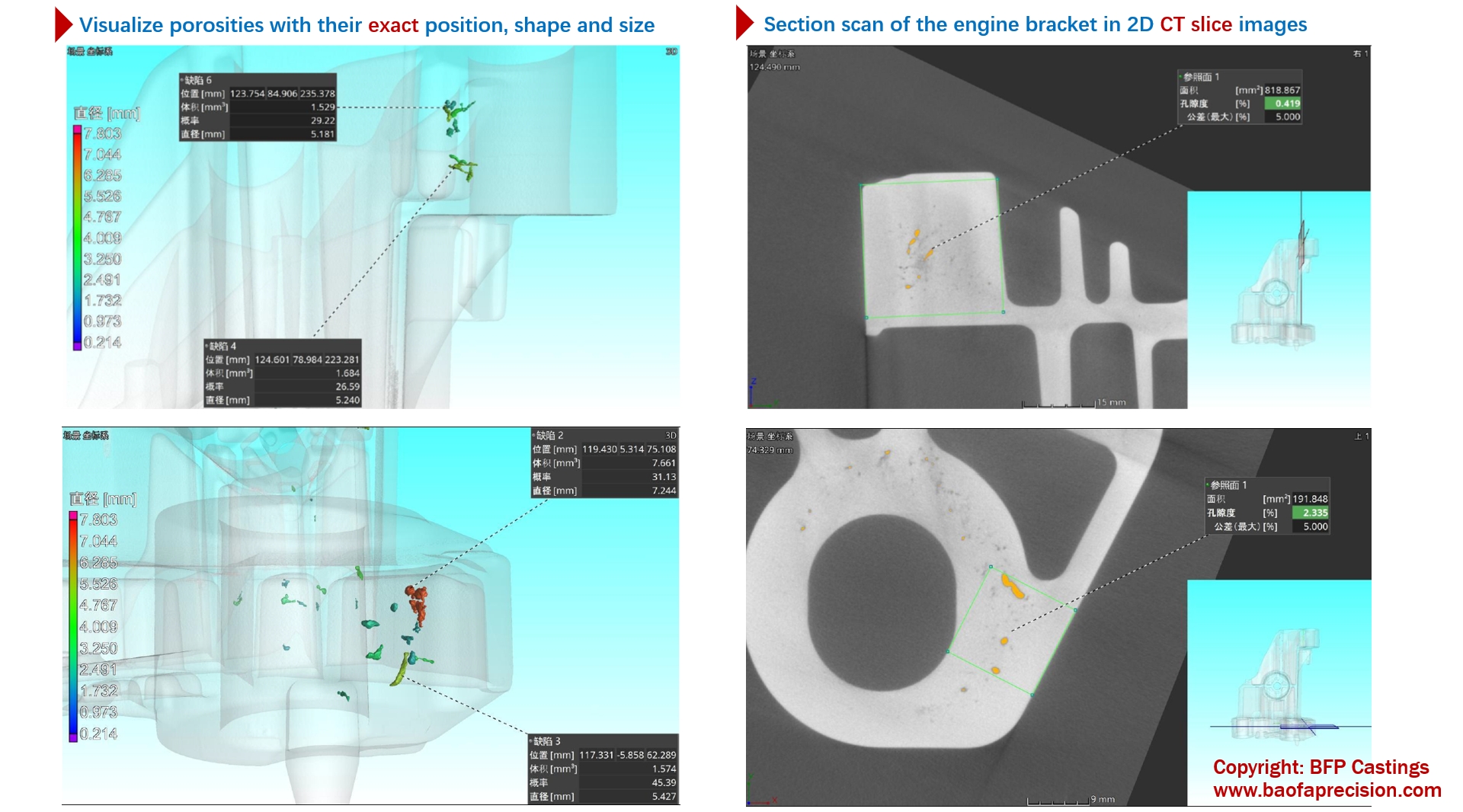

Powered by advanced industrial CT tools, engineers at BFP Castings can easily visualize and analyze porosity, inclusions and internal inconsistences which affecting mechnical integrity to ensure our cast aluminium parts meeting performance and durability criteria.

Key benefits of metal casting industrial CT scanning

Accurately and easily detect, quantify and visualize castings porosity in a combination of 2D and 3D views

The castings are not damaged and destroyed during the CT scanning process, this is especially important when the castings are safety critical and expensive

CT scanning creates a digital data record of a metal casting's internal structure for future reference and comparisons

CT scanning enables fast and efficient inspection of metal castings, resulting in time and cost savings

Quality metal casting by BAOFA Precision

BFP uses both permanent mold casting and pressure die casting technology to manufacturing structural, functional and safety critical castings used in many different industries such as automotive, off-highway and general mechanical engineering. With this cutting-edge non-destructive testing technology, the BFP team can detect potential hidden casting defects early in the design and manufacturing process. This innovative approach not only showcase our commitment to quality, but also postion BFP as one of the leading metal casting manufacturer and foundry.

Contact US today to learn more about our metal casting inspection solutions, our team is always available to answer your questions and developed a customized solution for your needs.