BFP newly developed chassis structural casting component made of AlSi10MnMg alloys with T7 heat treatment achieved the following mechanical properties: tensile strength ≥215 Mpa, yield strength between 150 to 180 Mpa, elongation ≥7%, better than our customer standards specified.

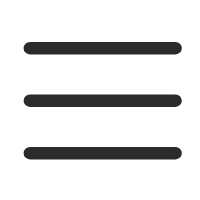

The major challenges for this aluminum structural casting development are to meet the higher strength with good elongation material properties, and in the meantime to strictly control the raw-cast geometry deformation within the tolerance of ±0.6 mm during the heat treatment process. With many rounds of trials and optimizations in the pressure die casting process and T7 heat treatment methods, the mechanical properties of test pieces have achieved the standard specification and also verified with accredited testing agency in March 2024. The details of sampling and testing results as the below shows:

As the full-service Tier 1 supplier, this product is delivered directly to the premium European OEM assembly plant, installed in the latest generation EV platforms. Fullfills the requirements of chassis structural casts with higher yield strength is another demonstration of the BFP Castings vast know-how in the aluminum high pressure die casting and heat treatment field.